Nuclear Power Plant Materials and Services

This guide details some key materials and services for nuclear plant projects, identifying local supply opportunities for Kenyan industry based on global data.

Note: Many specialized components require importation, but local manufacturing is possible for some. Please complete this form to inform policy development.

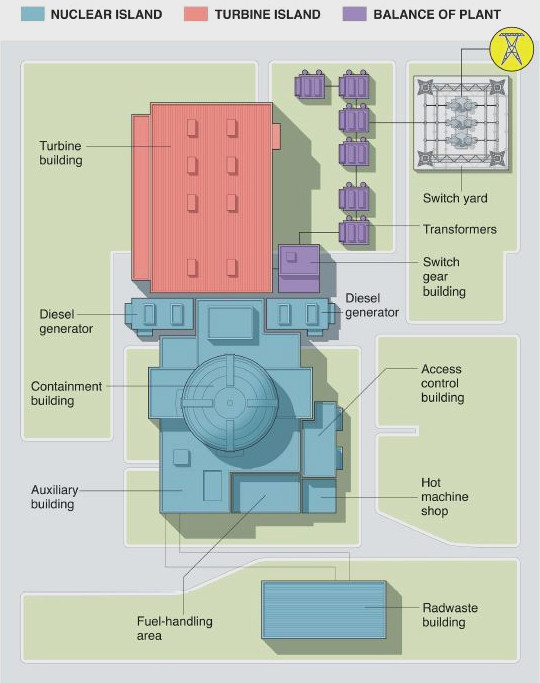

The nuclear power plant is divided into three main sections:

Simplified schematic showing Nuclear island, Turbine island and Balance of Plant island Source: Emirates Nuclear Energy Commission

Table of Contents

1. Nuclear Island: High Safety Standards (Highly Specialized – Requires International Partnerships)

The nuclear island contains the reactor vessel and primary cooling system. It needs extreme precision and quality control. International partnerships are crucial for the entire section with very minimal or no local participation.

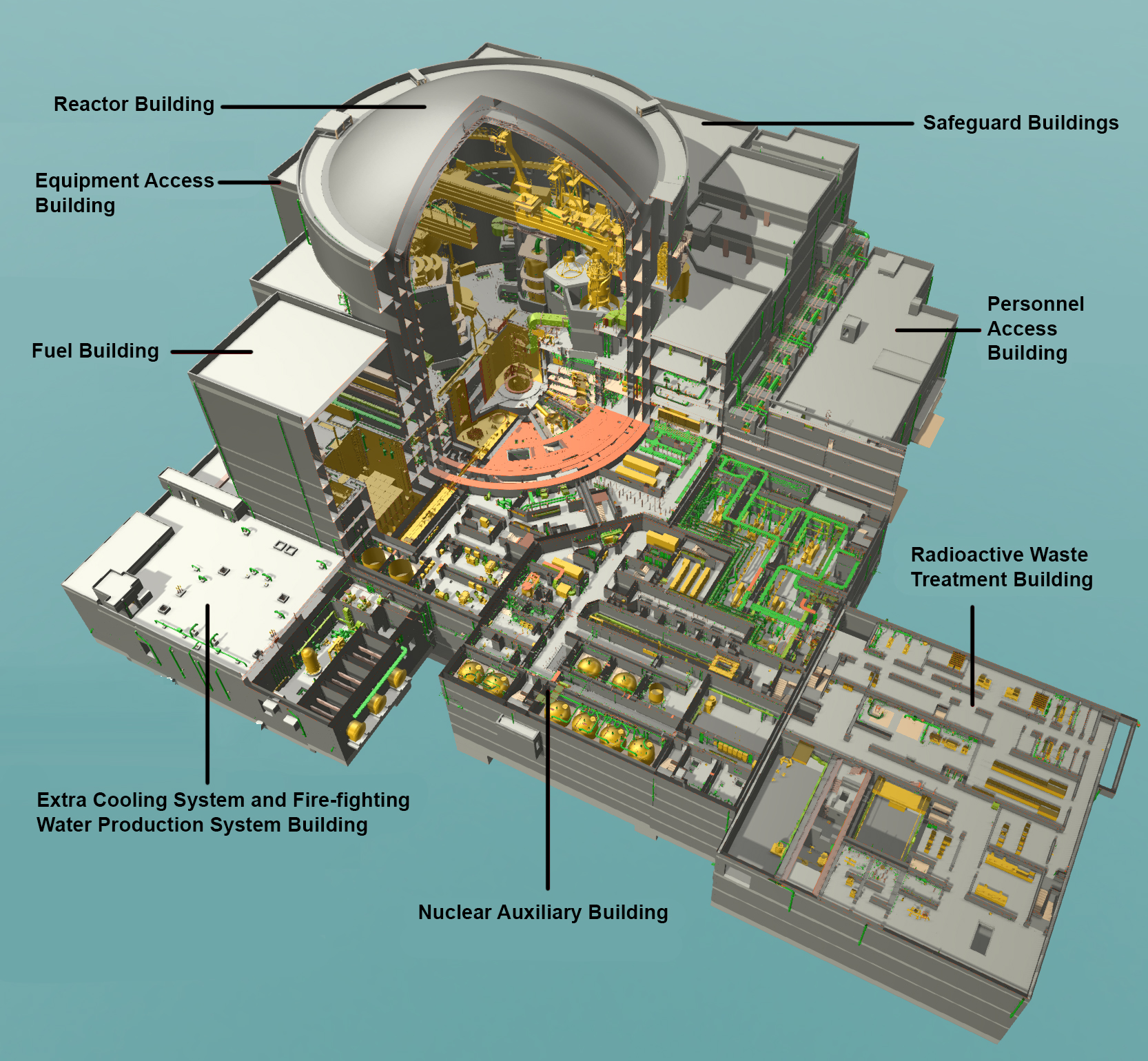

Chinese HPR 1000(Hualong 1) Nuclear Island Schematic Source: CGN-EDF HPR1000 GDA

Summary of Kenya's potential industrial capacity in Nuclear Island

| Industry | Potential |

|---|---|

| Construction & Civil Works | Concrete batching, rebar fabrication, formwork installation |

| Material Handling | Crane operation, heavy equipment operation, logistics support |

| Welding & Fabrication | Limited potential - requires specialized nuclear certification |

| Technical Support | Installation support, quality control assistance |

1.1. Reactor Pressure Vessels (RPVs)

Installation of Fuqing Unit 6 HPR1000 Reactor (1000MWe) in China's Fujian province Source: China National Nuclear Commission

The RPV is a thick-walled steel vessel that holds the nuclear fuel. It is very difficult to make and requires special manufacturing skills. A typical RPV like the HPR1000 has an inside diameter of 4.6 meters and height of 12 meters, weighing 330 tons. Making it requires huge forging presses of over 10,000 tonnes capacity.

Few companies around the world possess the capability to manufacture the RPV. The USA, for example, according to a 2018 Department of Energy report, even though the United States leads in global nuclear power generation, it relies on foreign suppliers for large nuclear components for its new reactors due to high costs.

For instance, the projected cost for establishing a domestic ultra-large forging facility capable of producing these components in the U.S. was approximately $2 billion (KSh 255.14 billion). A single forged pressure vessel can cost around $150 million (KSh 19.14 billion) to produce.

It would be quite costly for Kenya to set up shop for these huge presses, perhaps in the future with a highly developed nuclear program.

Key international manufacturers include:

Local Potential: Given the extreme material science, forging capacity, and cost ($2 billion setup), Kenya's current contribution is limited to support services. Kenyan companies can provide support structures, handling equipment, and installation help under the strict supervision of the international nuclear vendor.

1.2. Steam Generators

Steam Generator manufactured by Framatome delivered to Cruas-Meyss, France Source: World Nuclear News

Steam generators transfer heat from the reactor to create steam for electricity. They are huge, specialized heat exchangers that act as a primary barrier between the radioactive and non-radioactive loops. Typical steam generators are 21 meters tall and weigh up to 800 tons. Each contains 3,000 to 16,000 tubes made of corrosion-resistant alloys like Inconel 690, which demand extremely high precision welding and inspection standards. The Steam Generator, just like the RPV, requires immense forging and precision manufacturing capabilities. Major international manufacturers, who hold the intellectual property and unique production capabilities, include Shanghai Electric and Mitsubishi Heavy Industries.

Local Potential: As with the RPV, the complexity of materials (e.g., Inconel tubes) and manufacturing techniques makes local production unfeasible at present. Kenya's potential lies in providing robust support structures, specialized handling and transport logistics (as detailed in section 1.7), and installation and pre-commissioning assistance under the vendor's supervision.

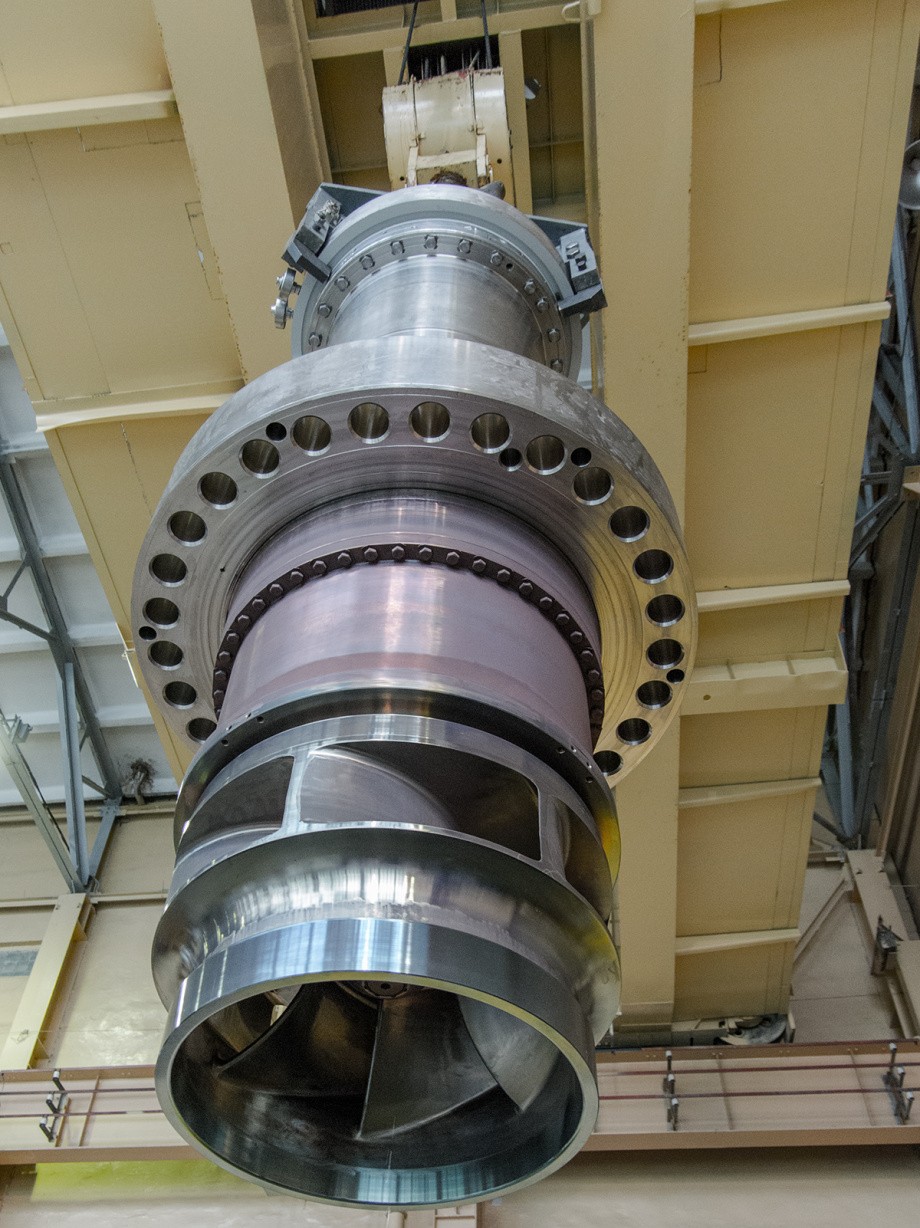

1.3. Primary Coolant Pumps

These pumps circulate high-pressure water through the reactor core, ensuring heat is removed safely. They must be extremely reliable to operate continuously for decades without failure. The pumps are 5–8 meters tall, weigh 50–100 tons, and use large motors up to 6.3 MW. They can deliver flow rates of over 20,000 m3/h at pressures up to 15 MPa. They are designed to last the full 60 years life cycle of a nuclear power plant. Only a few specialized companies worldwide (e.g., Curtiss-Wright, Flowserve, China's Harbin Electric) manufacture nuclear-grade coolant pumps that meet the strict safety standards (e.g., ASME Section III) for performance, seismic resistance, and reliability.

A Primary coolant pump. Source: World Nuclear News

Local Potential: The need for specialized materials (nuclear-grade stainless steel) and precision casting/dynamic balancing limits local manufacturing. Kenya's main potential is in providing non-nuclear auxiliary motor assembly services (if simplified components are used), support structures, heavy handling equipment for placement, and installation services under international QA/QC (Quality Assurance/Quality Control) supervision.

1.4. Containment Buildings

Image showing complete concreting of containment building at Zhangzhou 1 NPP in China's Fujian province Source: World Nuclear News

The containment building is the ultimate safety barrier, housing the reactor and critical safety systems. It is designed to withstand extreme events, including earthquakes, massive internal pressure surges, and a 400-ton aircraft crash.

Modern containments, such as the AP1000’s 45-meter-diameter, 65-meter-high steel-concrete hybrid, feature 1.2–2.4-meter-thick reinforced concrete walls with a 6–40 mm carbon steel liner (ASTM A516). The structure uses approximately 40,000 m3 of high-density concrete (typically 70 MPa) and over 5,000 metric tons of high-strength rebar (A615 Grade 75). The Chinese 3rd generation 1000MW reactor Hualong 1 uses a containment vessel of diameter 46m and height 69m, with two robust concrete shells of 1.3 m and 1.8 m.

For Kenya's nuclear plant, local construction companies can contribute significantly, provided they can meet special material and quality assurance requirements:

1. Special Radiation-Shielding Concrete:

- Requires high-density concrete with special aggregates like barite or magnetite.

- Must achieve low porosity for effective radiation protection.

- Must meet precise strength (e.g., 70 MPa) and placement specifications.

2. Steel and Rebar Requirements:

- High-strength rebar (ASTM A615 Grade 60 or 75) for structural integrity.

- Steel plates (ASTM A36 or A516) for the critical leak-tight containment liner.

Local Potential: This section represents Kenya's most significant potential for localization and technology transfer. Kenya has established capabilities in concrete batching, rebar fabrication, and large-scale formwork and general construction. However, achieving nuclear-grade quality requires:

- International Partnerships: To transfer expertise in high-density aggregate sourcing and high-strength concrete mix design.

- Certification: Local construction firms, welders, and NDT personnel (as noted in Section 1.6) must be certified to international nuclear standards (e.g., ASME, RCC-M) to handle the containment liner welding and high-strength rebar installation.

1.5. Other Critical Components

Fuel Assemblies, Fuel Rods, Control Rods, Valves and Piping

Fuel assemblies contain multiple fuel rods, which hold uranium oxide fuel pellets. The rods are made of zirconium alloys and require precision manufacturing under extremely clean, controlled conditions. Control rods absorb neutrons to control the nuclear reaction, using materials like boron carbide or hafnium.

Image showing a fuel assembly. Contains fuel rods containing uranium oxide fuel pellets. Source: World Nuclear Association

Local Potential for Fuel and Control Rods: Extremely Limited. The manufacturing involves highly specialized, proprietary technology (zirconium alloy cladding, uranium processing, and pellet fabrication) that is centrally controlled by a few international suppliers for proliferation and safety reasons.

Nuclear-grade valves and piping must withstand high pressure, temperature, and radiation while maintaining leak-tightness. This requires specialized material selection and stringent Non-Destructive Testing (NDT) of welds.

Local Potential for Valves and Piping: Kenya can engage in fabrication and installation of non-nuclear, auxiliary system piping and basic support piping. Critical primary circuit piping must be sourced internationally, but local welding and inspection personnel (certified to ASME standards) can be utilized for the installation of both primary and secondary circuits under direct supervision.

1.6. Welding Requirements for Nuclear Island

Welding is one of the most critical processes in nuclear plant construction, requiring the highest quality standards, especially for components like the RPV, primary piping, and containment liner. All welds are subject to 100% inspection using non-destructive testing methods.

Required Certifications and Standards:

Nuclear welding requires special certifications beyond standard welding qualifications:

- ASME Section IX (American Society of Mechanical Engineers) - Qualification standard for welding and brazing procedures

- RCC-M Code (French nuclear design and construction rules) - Design and construction rules for mechanical components of PWR nuclear islands

- AWS Certified Welding Inspector (CWI) - American Welding Society certification for welding inspectors

-

Rigorous Non-Destructive Testing (NDT) is mandatory:

- Radiographic (X-ray) Testing - ASTM E1742 Standard Practice for Radiographic Examination

- ASNT SNT-TC-1A - Standard for qualification and certification of NDT personnel

Local Potential:

This is a key area for high-value skills development. While specialized welding like Tube-to-tubesheet requires highly automated systems, Kenyan welders and NDT technicians can be trained and certified to perform containment liner welding, rebar splicing, and balance-of-plant (BOP) piping welds. Achieving nuclear certification (e.g., ASME or RCC-M qualifications) for hundreds of personnel represents a significant, long-term opportunity for local workforce upskilling and job creation.

1.7. Material Handling Equipment for Nuclear Island

Specialized equipment is essential to handle the extremely large, heavy, and irreplaceable nuclear components (like the 330-ton RPV and 800-ton Steam Generator) safely and precisely.

Key Equipment:

- Crawler Cranes: For heaviest components (RPV, Steam generator) with capacity typically 1,000+ tons.

- Polar Cranes: Special cranes permanently installed within the containment building for refueling and component replacement (1,000+ tons capacity).

- Self-Propelled Modular Transporters (SPMTs): For precise on-site movement of massive, multi-hundred-ton components.

Fangjiashan NPP Material Handling Equipment Specifications

The example of the Fangjiashan NPP demonstrates the scale of equipment needed:

| Equipment Type | Capacity | Primary Use at Fangjiashan | Manufacturer/Model |

|---|---|---|---|

| Crawler Crane | 1,600 tons | Reactor pressure vessel installation | Liebherr LR 1600/2 |

| Polar Crane | 1,200 tons | Containment building component handling | CNNC custom design |

| Gantry Crane | 380 tons | Turbine generator installation | ZPMC design |

| Tower Cranes | 32-50 tons | General construction at height | Multiple (Liebherr, Potain) |

| SPMTs (8-12 axles) | Up to 500 tons | Heavy component transport | Scheuerle/Kamag designs |

| Overhead Cranes | 5-100 tons | Workshop and auxiliary building operations | Various Chinese manufacturers |

Local Potential: While the largest, most specialized cranes (1000+ ton capacity) and SPMTs will be rented or leased from international specialists, Kenya's established construction industry can provide medium-capacity tower cranes (up to 50 tons), general overhead cranes (5-100 tons), heavy haul trucks, and general lifting gear (e.g., specialized slings and spreader beams). Most importantly, Kenyan personnel can be trained to operate and maintain this equipment, forming a highly skilled, certified rigging and lifting team, which is critical for all heavy-lift operations.

1.8. Human Resource Requirements

Operating a nuclear power plant requires a rigorously trained, highly disciplined workforce certified by the national nuclear regulator. Global best practice, followed in countries like Pakistan (for Hualong One) and the UAE (for Barakah), requires that personnel have a strong academic foundation before specialized training.

Operator Training Requirements (International Standards)

Academic Prerequisite: A bachelor's degree in engineering (mechanical, electrical, chemical, nuclear) or another STEM field is required for operators (IAEA Safety Reports Series No. 50).

Structured Training Pathway (2–3 years):

- Classroom Training (6–12 months): In-depth coverage of reactor systems, nuclear safety, and procedures (IAEA NP-T-3.12).

- Simulator Training (6–12 months): Full-scope control room simulations required by IAEA Safety Standards (IAEA SSG-39).

- On-the-Job Training: Hands-on work under licensed senior operators.

- Licensing Exams: Mandatory theoretical and practical examinations overseen by the national regulator (KNRA in Kenya).

Case Study: Pakistan's Hualong One Operators

Pakistan's operators for the K-2 and K-3 Hualong One reactors received multi-year operational training from the vendor:

- CNNC Training Centers: Included hands-on training at the Fuqing NPP full-scope Hualong One simulator (World Nuclear News, 2021).

- China National Nuclear Corporation (CNNC) Nuclear Power Institute of China (NPIC): For advanced systems training (CNNC Official Website).

Foundational Safety Training

All personnel must complete safety training covering:

- Radiation protection (IAEA GSR Part 3).

- Human performance and safety culture (INSAG-4).

- Emergency preparedness (IAEA GS-R-2).

- Quality assurance (QA/QC) (IAEA GS-G-3.1).

Local Potential: This is Kenya's highest area of potential for complete localization. Kenya has a strong foundation of STEM graduates from institutions like the University of Nairobi, JKUAT, and Moi University. The strategy should be to create nuclear-specific university and TVET curricula and partner with international vendors and the IAEA to provide the necessary multi-year, specialized, and certified training. This will ensure that all operations, maintenance, and technical support staff are Kenyan citizens, securing long-term, high-value employment.

Nuclear Island Components, Materials and Equipment Overview

| Component | Primary Materials | Key Properties | Machines & Equipment Needed | Kenya's Local Potential |

|---|---|---|---|---|

| Reactor Pressure Vessel | Low-alloy steel (SA-508, SA-533), Stainless steel cladding | High strength, fracture toughness, radiation resistance | 10,000+ tonne forging presses, precision welding equipment | Installation, General Support Structures |

| Steam Generators | Inconel 600/690 (tubes), Carbon steel (shell) | Stress corrosion resistance, high-temperature strength | Tube bending machines, precision orbital welders, NDT equipment | Installation, Heavy Component Transport Logistics |

| Control Rod Systems | Boron carbide, Hafnium, Stainless steel | High neutron absorption, structural integrity | Precision machining tools, clean room environment | Extremely Limited (Highly Specialized/Proprietary) |

| Primary Coolant Pumps | Nuclear-grade stainless steel (304L, 316L) | Corrosion resistance, high mechanical strength | Precision casting equipment, dynamic balancing machines | Auxiliary Motor Assembly, Installation, Support Structures |

| Containment Structure | High-strength concrete, Carbon steel liner, High-strength rebar | Radiation shielding, structural integrity, seismic resistance | Concrete batching plants, slipform systems, heavy cranes, welding equipment | Highest Potential: Concrete supply, Rebar fabrication, Installation, Certified Welding (Steel Liner) |

| Material Handling | Various structural steels | Heavy load capacity, precision movement | Crawler cranes (1,600-ton), polar cranes (1,200-ton), SPMTs (500-ton) | Operation and Maintenance of Medium-Capacity Cranes, Rigging, Transport |

2. Turbine Island: Power Generation (Conventional Tech – Localization Opportunities)

The Turbine Island consists of the turbine and generator. The island functions to convert high-pressure steam from the Nuclear Island's steam generators into rotational mechanical energy (turbine), which is then converted into electrical energy by the generator. While the design is nuclear-specific, the core manufacturing technology is non-nuclear. This offers significant localization potential; particularly in the services, as the machinery are still significantly highly specialized to be sourced from local manufacturers.

Summary of Kenya's potential industrial capacity in the Turbine Island

| Industry | Potential |

|---|---|

| Construction & Civil Works | High Potential: Extensive civil and structural works for turbine foundations, building, and support structures |

| Material Handling | High Potential: Operation of large gantry cranes and heavy equipment for component installation |

| Welding & Fabrication | Moderate Potential: Fabrication of non-nuclear piping, tanks, support structures, and heat exchanger shells |

| Technical Support | High Potential: Electrical wiring, installation, and commissioning of conventional systems (e.g., generator auxiliaries, switchgear) |

2.1. Steam Turbines and Generators

The massive Steam turbine and generator form the "Conventional Island" of the nuclear power plant. This means it's a section that is typically found in many other types of power generating plants such as Geothermal and thermal plants.

Image showing inside a Nuclear Power Plant's turbine hall. Source: Bloomberg

The Steam Turbine must operate continuously and reliably for maximum base-load power generation. For large 1000 MWe nuclear power plants, low-speed (1,500 rpm or 1,800 rpm) turbines, such as GE Vernova's Arabelle, are frequently selected for their high reliability, robustness, and resistance to blade erosion, evidenced by their use in major new-build projects like the Hinkley Point C project in the UK and the Akkuyu Nuclear Power Plant in Turkey. The Generator is coupled to the turbine and converts this mechanical energy into electricity, which is then fed to the grid.

- Both the turbine and generator are designed for the full 60-year operational life of the nuclear plant.

- Major Maintenance (overhauls) is typically scheduled during refueling outages. Typically on every second to third fuelling cycle, usually every four to six years, requiring the dismantling, inspection, and possible replacement of internal components like turbine blades and generator windings.

- Routine Maintenance is continuous and condition-based, involving monitoring of lubrication systems, temperature, and vibration analysis.

These highly complex components are manufactured by a few global technology leaders, including:

- Shanghai Electric: A major domestic supplier supporting the vast expansion of China's nuclear fleet.

- Mitsubishi Heavy Industries (MHI): Supplied key turbine equipment for the world's first AP1000 reactors at the Sanmen and Haiyang Nuclear Power Stations in China.

- Doosan Enerbility: Has supplied components to numerous domestic South Korean plants and the Barakah plant in the UAE.

- GE Vernova

- Siemens Energy

- Ansaldo Energia

Local Potential: While the main turbine-generator sets are imported, local industry can support in the construction of deep turbine foundations and the installation support for this heavy machinery. Local electrical firms can handle the installation, testing, and commissioning of the generator's auxiliary and control systems.

2.2. Condensers, Feedwater Heaters, and Moisture Separator Reheaters (MSRs)

These large heat exchangers and steam processors are essential components of the Conventional Island, working to maximize thermodynamic efficiency by recovering heat and drying steam before it returns to the turbine or the reactor system.

Condensers: These are massive shell-and-tube heat exchangers located below the low-pressure turbine. Their primary function is to cool exhausted steam back into water (condensate). The tubes must be highly resistant to corrosion from cooling water (seawater, river water, etc.). Common materials used in their construction include Titanium, Stainless Steel (316L), or Copper-nickel alloys. The outer condenser structures/shells are typically made using carbon steel.

Image showing a Nuclear Power Plant's condenser units outside a turbine hall. Source: Nooter Construction

Feedwater Heaters: These are shell-and-tube heat exchangers that use extracted steam from the turbine stages to pre-heat the condensate. This process significantly improves the overall plant efficiency by reducing the heat required from the reactor/steam generators. They require precise tube-to-tubesheet welding during fabrication.

Moisture Separator Reheaters (MSRs): These are critical for high-reliability turbine operation. Located between the high-pressure and low-pressure turbine sections, MSRs remove moisture from the steam and reheat it, which is essential for protecting low-pressure turbine blades from erosion caused by wet steam. They utilize stainless steel components.

Local Potential in Fabrication and Supply:

Although this equipment is highly specialized, its non-nuclear nature presents a significant opportunity for local participation and supply chain integration.

The materials, such as the tubes which are sometimes made of Titanium, require highly specialized manufacturing processes. This involves specialized machinery, such as high-precision tube drawing and rolling mills and advanced orbital welding systems for seamless fabrication.

Manufacturing these specific items without pre-existing, certified machinery results in 'First of a Kind' (FOAK) equipment, thereby raising initial capital costs and requiring substantial human resource training.

The condenser shells, often made of heavy-duty carbon steel, can potentially be manufactured in Kenya, as there are currently existing local companies with years of experience in fabricating pressure vessels and heat exchangers. However, further research is needed to determine the precise manufacturing capacity of local firms, including the maximum specifications (e.g., diameters, thicknesses, and tolerances) of existing plate rollers and bending machines.

This information is essential for formulating effective policy and increasing cooperation between local industry firms, the government, and the potential NPP supplier. In summary, there are significant opportunities for local industry to participate in the supply chain:

2.3. Cooling Water and Auxiliary Piping Systems

Extensive piping is required for circulating cooling water, condensate, and high-pressure steam lines, typically about 2km in length.

The materials used in piping include Carbon steel (ASTM A106, A53) and Stainless steel (ASTM A312). High-pressure steam lines use creep-resistant low-alloy steels (e.g., P22, P91).

Local Potential: Local manufacturers can supply a substantial portion of the conventional piping components (fittings, flanges) and provide the specialized installation and non-destructive testing (NDE) services.

2.4. Welding Requirements for Turbine Island (Conventional Power Standards)

Welding must adhere to conventional power plant codes, though with strict Quality Assurance/Quality Control (QA/QC) protocols to ensure the integrity of the power generation cycle.

Required Certifications and Standards:

Welding procedures must meet the following standards, which are essential for pressure boundary and structural integrity:

- High-Pressure Piping: Welding procedures must comply with ASME B31.1 (Power Piping). This involves pre-heat and post-weld heat treatment (PWHT) for creep-resistant alloy steels used in main steam lines.

- Heat Exchangers: Tube-to-tubesheet welds require automated orbital welding for high integrity.

- Structural Welding: Welds for supports and general structures must comply with AWS D1.1 (Structural Welding Code).

- Pressure Boundary Welds: Welders and inspectors must hold ASME Section IX qualifications for pressure boundary welds.

2.5. Material Handling Equipment (Turbine Island Specific)

The primary handling requirement is for the installation and overhaul of the generator and turbine rotors. Local industry has high potential in the operation of this large gantry crane and heavy equipment for component installation.

2.6. Human Resource Requirements (Turbine Island)

Specialized technical staff with experience in large rotating machinery and thermal power generation are critical.

- Turbine Operators: Licensed personnel specializing in turbine startup, load changes, and shutdown procedures.

- I&C Technicians: Responsible for the calibration and maintenance of the conventional control systems (I&C) that regulate the turbine and generator auxiliaries. The design emphasizes uniformity for improved maintenance.

- Mechanical Maintenance Engineers: Experts in precision alignment and balancing of high-speed rotating equipment, including turbine rotors and pump sets.

Turbine Island Components and Materials Overview

| Component | Material Used (Local Manufacture Potential) | Local Manufacturing/Fabrication Activity |

|---|---|---|

| Conventional Piping & Accessories | Carbon Steel (e.g., ASTM A53, A106), Stainless Steel (e.g., ASTM A312) | Supply of standard straight pipe sections, conventional fittings (flanges, elbows), specialized spool fabrication, pipe support manufacturing, and non-destructive testing (NDE) services. |

| Condenser & Feedwater Heater Shells | Carbon Steel, Stainless Steel (General Grades) | Fabrication of the large outer shells, water boxes, and end covers for the main condensers and auxiliary heat exchangers (excluding the specialized tubes themselves). |

| Auxiliary Water Tanks & Storage Vessels | Carbon Steel, Stainless Steel | Full manufacturing of condensate storage tanks, demineralized water tanks, and other balance of plant vessels, including internal structures and supports. |

| Turbine Hall Structural Steelwork | Carbon Steel (Structural Grades) | Fabrication and erection of the massive steel structure for the Turbine Hall, equipment platforms, access stairs, and pipe racks. |

| High-Pressure Piping Spools | Low-Alloy Steel (e.g., P22, P91) (Material is imported) | Local cutting, bending, spool fabrication, and provision of specialized welding and Post-Weld Heat Treatment (PWHT) services, which require high-level certified expertise. |

3. Balance of Plant (BOP): Highest Local Content Potential

The Balance of Plant (BOP) encompasses all auxiliary (support) systems and infrastructure outside the Nuclear and Turbine Islands. This means they are all infrastructure necessary to ensure the plant operates normally. The BOP encompasses, cooling water systems (pumps, piping, and heat exchangers), and cooling towers. They also include electrical infrastructure including transformers and switchyards. This section provides the highest percentage of local content opportunity due to its use of conventional, non-nuclear specific technology. The image below shows Roopur Nuclear Base in Bangladesh. All structures that are not the nuclear island and turbine island encompass the Balance of Plant.

Image showing Roopur Nuclear Base in Bangladesh. Source: IAEA

Summary of Kenya's potential industrial capacity in the Balance of Plant (BOP)

| Industry | Potential |

|---|---|

| Construction & Civil Works | Very High Potential: Roads, drainage, administration buildings, cooling towers, and general plant foundations |

| Material Handling | High Potential: General logistics, heavy equipment operation, and transport support |

| Welding & Fabrication | High Potential: Fabrication of steel structures, non-safety-related tanks, cable trays, and busbars |

| Technical Support | Very High Potential: Electrical system installation, water treatment system design and operation, fire protection, and HVAC installation |

3.1. BOP Systems Overview (Highest Local Potential)

The BOP systems for a nuclear plant mirror the auxiliary systems of a large-scale fossil-fuel thermal power project. It involves extensive civil works, including the construction of the generator rooms, cooling towers, intake and discharge structures, and administrative buildings. Beyond the physical infrastructure, it encompasses the mechanical and electrical systems required to convert steam into electricity and support the nuclear island.

Image showing some of Roopur Nuclear Base in Bangladesh. Source: IAEA

These systems are essential for plant functionality but do not handle radioactive materials. The systems include:

- Circulating Water System (CWS): Large pumps and piping for moving cooling water from the water source (or cooling towers) to the condenser. This system manages the ultimate heat sink for the plant, requiring massive intake and discharge structures designed to handle enormous flow rates while minimizing environmental impact on aquatic life.

- Fire Protection, Detection & Alarm System: A highly redundant safety layer consisting of dedicated fire water storage tanks, multiple pumping stations (electric and diesel-driven), and a network of sensors. It provides real-time monitoring of all non-nuclear zones, including the turbine hall and administrative blocks.

- Water Treatment Plant (WTP): Advanced systems for treating raw water to produce ultra-pure demineralized water. This prevents corrosion and scaling in the steam generators through multi-stage filtration, reverse osmosis (RO), and ion-exchange processes.

- Fuel Oil Handling System: A robust storage and transfer system that services the Emergency Diesel Generators (EDGs) and auxiliary boilers. It includes seismically qualified underground storage tanks and purification systems to ensure fuel reliability during potential station blackout scenarios.

- Electrical Distribution & Switchyard: This includes the main step-up transformers that connect the plant to the high-voltage grid, as well as the auxiliary power system ("house power") that steps down voltage to run the plant’s own heavy machinery, lighting, and cooling systems.

- Compressed Air Systems: Divided into "Instrument Air" and "Service Air." Instrument air is maintained as extremely dry and oil-free to operate sensitive pneumatic valves and actuators, while service air provides power for maintenance tools and general plant cleaning.

- HVAC for Non-Nuclear Buildings: Specialized Heating, Ventilation, and Air Conditioning systems designed to maintain precise environmental conditions for sensitive electronic equipment in the control rooms and electrical galleries, ensuring equipment longevity and operator safety.

- Auxiliary Steam System: Provides the necessary steam for plant heating, deaerator "pegging" during startup, and other process requirements when the main reactor is not operating at full power.

- Potable & Service Water Systems: Provides treated water for domestic use within the administrative buildings and supplies non-critical cooling water for various mechanical components throughout the turbine island.

3.2. Cooling Towers and Auxiliary Buildings (Civil Works Opportunities)

Cooling towers are massive, civil structures engineered to act as the plant's ultimate heat sink by dissipating waste thermal energy into the atmosphere. While coastal plants or plants near large water bodies may utilize "Once-Through Cooling" via large water bodies, inland sites or those with strict environmental thermal-discharge limits rely on these structures to maintain optimal steam cycle efficiency. Their construction represents one of the largest continuous concrete pouring operations in a power project.

Natural draft cooling tower facilitating high-volume heat exchange. Source: Duke Energy

- Engineering & Materials: The hyperboloid shell is typically constructed using high-performance reinforced concrete (25-40 MPa) designed for extreme durability against chemical leaching and thermal cycling. This requires massive quantities of carbon steel rebar (A615 Grade 60 or 75). The internal "fill" or "packing"; which maximizes the water-to-air contact area; is usually comprised of UV-resistant PVC or polypropylene.

- Auxiliary Building Scope: Beyond the towers, the BOP civil scope includes Pump Houses, Water Treatment Buildings, and Diesel Generator Bunkers. These require seismically qualified foundations, specialized utility tunnels (culverts) for heavy piping, and chemical-resistant coatings for concrete surfaces.

- Local Potential (Supply Chain): Kenyan cement manufacturers and aggregate suppliers can provide most of the raw materials, provided they meet the stringent Nuclear Quality Assurance (NQA-1) or equivalent standards. Local concrete batching plants have the opportunity to supply the specialized mixes required for continuous pour construction techniques used in the tower shells.

- Local Potential (Construction): Tier-1 local civil construction firms possess the heavy machinery and labor force required for site grading, deep foundation piling, and the erection of auxiliary structures. The complexity of the cooling tower shell provides a unique opportunity for local firms to enter strategic partnerships with international nuclear vendors for the specialized climbing formwork execution.

3.3. Transformers and Switchyards (Electrical & Logistics)

The switchyard acts as the plant's electrical gateway, stepping up the generated voltage (typically 20kV to 25kV) to transmission levels (220kV or 400kV) to minimize energy loss across the national grid. This infrastructure provides the critical link between the plant's generator and the national electrical transmission grid, covering the main step-up transformers and the high-voltage switchyard equipment.

Component Materials and Specifications:

The main electrical equipment requires highly specialized materials designed for decades of outdoor exposure and high-fault currents to handle extreme voltages and ensure plant safety:

- Transformers: These units utilize specialized steel cores for high magnetic efficiency, high-purity copper or aluminum windings, and large carbon steel tanks. They also require high-grade dielectric insulating oils for cooling and arc suppression.

- Switchyard Components: Infrastructure requires high-conductivity copper or aluminum busbars and high-voltage porcelain or polymer composite insulators. Key equipment includes circuit breakers, disconnect switches, and surge arresters. Structural supports are constructed from hot-dip galvanized steel to prevent atmospheric corrosion.

- Electrical Wiring/Cabling: All cables must be Low Smoke Zero Halogen (LSZH) and meet specialized standards for fire retardancy. Critical safety-related paths utilize insulation types such as XLPE, EPR, or mica tape to ensure functionality under high-temperature or radiation-stress conditions.

Currently, there are no transformer manufacturers in Kenya capable of producing the specialized, high-capacity, high-voltage transformers required for a nuclear power plant. These critical, long-lead components must be imported from certified global vendors.

- Local Potential (Services): Local electrical engineering firms can manage the comprehensive installation, testing, and commissioning of the switchyard components. This includes the assembly of gantry structures, cable laying, precision termination, protection relay calibration, and final grid synchronization.

- Local Potential (Fabrication): Opportunities exist for the local fabrication of auxiliary supporting infrastructure, such as cable management systems, non-critical steel transformer tanks, and busbar supports.

- Earthing & Lightning Protection: Kenyan firms can provide full-scope services for the installation of complex earthing grids and lightning protection systems, which are vital for protecting sensitive.

3.4. Welding Requirements for Balance of Plant (BOP)

Welding for the Balance of Plant uses standard industrial construction codes. This creates many opportunities for qualified local contractors to participate in the project.

- Structural Welding: All steel frames for buildings, pipe supports, and water intake systems must follow the AWS D1.1 (Structural Welding Code).

- Process Piping: Piping for water, fire safety, and air systems must be welded according to ASME B31.3 (Process Piping) standards.

- Tank and Vessel Fabrication: Storage tanks for water and fuel must meet the API 650 (Welded Tanks for Oil Storage) standard.

- Quality Control: Local firms can provide inspection services such as X-ray and ultrasonic testing to verify weld quality.

3.5. Emergency Power and Critical Auxiliaries (Diesel Generators)

Emergency Power Systems provide immediate backup electricity to essential safety equipment if the main power grid fails. This system uses highly reliable Emergency Diesel Generators and large battery banks.

These generators are large engines often located in strong concrete buildings designed to withstand earthquakes. The fuel tanks and pipes must follow strict safety and environmental rules.

Key Requirements and Standards:

- Reliability: Generators must start and reach full power in less than 10 seconds as required by the IEEE 387 standard.

- Earthquake Safety: The entire generator system must stay operational even after a major earthquake.

- Fuel Handling: Systems for storing and moving diesel must follow NFPA 30 codes for handling flammable liquids.

Local Potential: While the engines are imported, local companies can build the concrete shelters and install the fuel tanks and pipes. Local electrical firms can also set up the wiring and battery systems and provide long-term maintenance services.

3.6. Water Treatment Plant (WTP) and Chemical Services

The Water Treatment Plant is a vital part of the Balance of Plant. It prepares the huge amounts of high-purity water needed for the steam cycle and cooling systems. Keeping the water pure is essential to prevent rust and damage to the expensive metal parts in the turbine and piping.

- Water Purification: This system uses filters and reverse osmosis to remove minerals and salts from raw water. The goal is to produce demineralized water that meets strict quality standards.

- Chemical Dosing: Technicians add specific chemicals to the water to control its pH levels. This helps stop corrosion and prevents the buildup of scales inside the boilers and pipes.

- Condensate Polishing: This process cleans the water that returns from the condenser. It removes any tiny metal particles or impurities before the water is pumped back into the steam system.

- Waste Water Management: The plant must also treat any waste water produced during the cleaning process. This ensures that any water released back into the environment is safe and meets local regulations.

Local Potential: Kenyan companies with experience in industrial water treatment can provide many services here. Local firms can design and supply the filtration systems, tanks, and piping. There are also long-term opportunities for local chemical suppliers to provide the volumes of resins and water-treatment chemicals needed for daily operations.

3.7. Site Infrastructure, Physical Security, and Access Control

Site infrastructure includes all the buildings and barriers needed to support the plant and keep it secure. This area offers the best opportunities for local civil and electrical contractors.

Key Components and Requirements:

- Physical Security Systems: This includes building strong boundary walls, security fences, vehicle barriers, and guard towers. It also involves installing cameras and motion sensors that meet international safety guidelines.

- Site Buildings and Roads: Construction of the main office buildings, training centers, warehouses, and the network of roads across the site.

- IT and Data Networks: Setting up the computer networks for offices and staff. This system is kept completely separate from the reactor control networks for safety.

Local Potential: Kenyan companies can handle almost all site work. This includes clearing the land, building roads, and constructing all non-nuclear buildings using local concrete and steel. Local security companies can also be trained to install and maintain the electronic access systems.

3.8. Human Resource Requirements (BOP)

The Balance of Plant needs many different types of technical workers. Many of these roles require skills that are common in other large industries like oil, gas, or manufacturing.

- Civil Maintenance Staff: Workers who can repair and maintain concrete structures, roads, and utility tunnels.

- Water Chemistry Technicians: Staff who run the water treatment plant to keep water pure and manage chemical levels.

- Logistics and Warehouse Managers: Professionals who track the thousands of spare parts needed to keep the plant running for 60 years.

- Security and Fire Safety Personnel: Teams trained to follow strict security rules and respond to emergencies using the fire protection system.

- Mechanical and Electrical Technicians: Skilled staff to maintain pumps, motors, and high-voltage equipment in the switchyard.

Balance of Plant Components and Materials Overview (Updated)

| Area | Localization Potential | Specific Opportunity for Local Industry |

|---|---|---|

| Civil & Site Works | Very High | All aspects of concrete supply, rebar bending/installation, site road construction, security fencing, and construction of administrative/auxiliary buildings. |

| Piping Systems (Conventional) | High | Fabrication and installation of service water, fire protection, and domestic water piping (using Carbon and Stainless Steel grades). |

| Electrical & Instrumentation (I&C) Installation | Moderate | Installation of cable trays, laying and termination of low-voltage cables, general lighting systems, and complex earthing/grounding networks. |

| HVAC & Ventilation | Moderate | Sheet metal fabrication of ductwork, installation of non-critical ventilation units and filtration systems for conventional and administrative buildings. |

| Emergency Power & Auxiliaries (EDGs) | Moderate | Civil construction of EDG bunkers, installation of fuel tanks/piping, full-scope maintenance services, and electrical installation. |

| Physical Security & Access Control | Very High | Civil construction (security walls, roads, fences), electrical wiring and installation of security hardware, IT network integration. |

4. Summary of Local Potential by Industry

The table below summarizes the potential for local industry participation across the Nuclear Island, Turbine Island, and Balance of Plant sections.

| Industry/Sector | Section (Local Potential Level) | Specific Local Opportunities (Materials & Services) | Required Standards/Certification Example |

|---|---|---|---|

| Construction & Civil Works | Nuclear Island (Limited) BOP (Very High) |

Supply of aggregate and cement, concrete batching (including high-density concrete), rebar fabrication and installation (A615 Grade 75), general plant foundations, roads, drainage, administrative buildings, and cooling towers. | Structural integrity & seismic resistance; High-strength concrete (70 MPa), Structural Welding (AWS D1.1). |

| Welding & Fabrication | Nuclear Island (Very Limited) Turbine Island (Moderate) BOP (High) |

Fabrication of non-nuclear piping spools, pipe supports, heat exchanger shells (Carbon Steel), auxiliary water tanks, cable trays, busbar supports, and structural steelwork for the Turbine Hall and BOP buildings. | ASME Section IX (pressure welds), ASME B31.1 (High-Pressure Piping), AWS D1.1 (Structural), API 650 (Tanks); Non-Destructive Examination (NDE) per ASNT SNT-TC-1A. |

| Non-Destructive Testing (NDT) & Inspection | All Islands (High) | Radiographic (X-ray) testing of welds, ultrasonic testing (UT) for thickness measurements and flaw detection, magnetic particle testing (MT), dye penetrant testing (PT) for surface flaws, visual inspection (VT), and advanced phased array ultrasonic testing (PAUT) for critical components. | ASNT SNT-TC-1A or ISO 9712 certification for NDT personnel; ASTM E1742 (Radiographic Testing), ASTM E1417 (Dye Penetrant), ASTM E709 (Magnetic Particle), ISO 17640 (Ultrasonic Testing). |

| Material Handling & Logistics | All Islands (High) | Operation of heavy equipment (Crawler, Tower, Gantry cranes), logistics support for component transport, operation of Self-Propelled Modular Transporters (SPMTs), and local supply of specialized lifting gear. | Rigorous safety protocols, Certified Crane Operators (1,000+ tons capacity), Heavy Haulage Permits and Expertise. |

| Electrical Engineering & Installation | Turbine Island (High) BOP (Very High) |

Installation, testing, and commissioning of the generator's auxiliary and control systems, high-voltage switchyard components, cable laying (fire-retardant, low-smoke, halogen-free cables), earthing/grounding networks, and general lighting systems. | IEEE/IEC standards for high-voltage systems; Fire protection system codes; High-level technical commissioning expertise. |

| Instrumentation & Control (I&C) | All Islands (Moderate to High) | Installation of sensors, transmitters, control valves, pressure/temperature indicators, Distributed Control System (DCS) cabling, safety instrumented systems (SIS), calibration of measurement devices, installation of reactor protection systems (RPS), and maintenance of process control instrumentation. | ISA/IEC 62443 (Cybersecurity), IEC 61508/61511 (Functional Safety), ISA Certified Control Systems Technician (CCST), ISA Certified Automation Professional (CAP), vendor-specific DCS/PLC training. |

| ICT & Computer Systems | All Islands (Moderate) | Installation and maintenance of plant computer systems, data networks (fiber optic/ethernet), cybersecurity implementation, SCADA system support, Plant Information (PI) system management, database administration, software validation and verification, and IT infrastructure for administrative systems. | ISO/IEC 27001 (Information Security), NIST Cybersecurity Framework, ISA/IEC 62443 (Industrial Automation Security), CompTIA Security+, Cisco Certified Network Associate (CCNA), vendor-specific DCS/SCADA training. |

| Piping Systems & Mechanical Installation | Turbine Island (High) BOP (High) |

Installation of all conventional piping systems (service water, fire protection, domestic water), specialized Post-Weld Heat Treatment (PWHT) services for high-pressure lines, and supply of standard pipe fittings (flanges, elbows). | ASME B31.3 (Process Piping), ASME B31.1 (Power Piping); Corrosion resistance standards (e.g., Titanium/Stainless Steel for condenser tubes/shells). |

| Water Treatment & Chemical Services | BOP (Very High) | Design, supply, and operation of the Water Treatment Plant (WTP), including demineralization and reverse osmosis systems; supply of industrial chemicals; and waste stream management. | Drinking water standards; Boiler feedwater quality (low conductivity); Environmental compliance. |

| Human Capital Development & Technical Support | All Islands (Critical) | Supply of engineers and technicians (mechanical, electrical, I&C, ICT, NDT) for installation support, quality control assistance, specialized training (e.g., in ASME nuclear codes), and long-term maintenance staff including ICT technicians, NDT inspectors, and I&C specialists. | IAEA Safety Reports Series, IAEA TECDOC-1057 (STEM/Engineering degree prerequisites), CNNC/Vendor-specific simulator training and national licensing exams, ASNT/ISO 9712 for NDT. |

| Manufacturing (Direct Component Supply) | Nuclear Island (None) | Manufacture of the specialized, heavy components (RPV, Steam Generators, Primary Coolant Pumps, Main Transformers) must be imported due to ultra-high precision, certification, and specialized forging/machining equipment requirements. | ASME Boiler and Pressure Vessel Code (Section III, Nuclear), RCC-M Code. |

Building a nuclear power plant demands very high safety standards. While the nuclear island requires specialized international expertise, the turbine island and balance of plant offer significant local opportunities. Strategic partnerships, human capital investment, and progressive localization will integrate Kenya into the nuclear energy world, fostering high-tech industries and skilled labor.